Manufacturing success is a matter of accuracy — deadlines need to be hit, quality needs to be controlled, and teams need to collaborate across departments. But too many companies still use siloed systems that distribute data among spreadsheets, emails, and legacy apps. Such fragmentation opens you up to delays, miscommunication, and inconsistent quality standards. To help tackle these challenges, manufacturing leaders are embracing the project management tools that unite communication, scheduling, data, and approvals into one connected platform.

Lark offers this integrated environment, allowing production teams to monitor progress, ensure quality standards, and keep the production flowing. And by centralizing processes into a single collaborative workspace, it guarantees production goals are on track, quality standards are maintained, and teams have the transparency to pivot fast when priorities shift.

Lark Base: Building structured visibility into production

Manufacturing involves countless moving parts, from supplier data and material inventories to production milestones and quality metrics. Without structure, this information becomes unmanageable. Without a filing system, this information becomes unmanageable. Lark Base provides manufacturing teams with a customizable platform for creating central databases that monitor each stage of production.

They could also configure custom views to monitor vendor compliance, manufacturing status, or quality checks. Dashboards highlight important KPIs like throughput or defect rates, while connected records trace supplier performance back to manufacturing. By turning fragmented data into unified insight, Base keeps managers in contact with the complete context of manufacturing and enables them to reduce hazards early.

Lark Messenger: Coordinating production teams in real time

Production schedules change quickly, and delays occur when missives don’t keep up between divisions. Lark Messenger keeps teams aligned with real-time conversations tied to workflows.

Manufacturing managers can create dedicated channels for production lines, supplier coordination, or quality control teams. Files such as inspection reports or updated process instructions remain attached to conversations, reducing the need to search across emails. Pinned messages highlight urgent updates, while persistent histories preserve the reasoning behind adjustments. By transforming chat into a driver of accountability, Messenger ensures that production teams respond quickly and consistently to changes on the factory floor.

Lark Calendar: Keeping schedules on track

Manufacturing timelines depend on careful scheduling, from machine maintenance to shipment deadlines. Lark Calendar offers a transparent system for managing schedules and ensuring tasks are completed on time.

Repeating events aid production teams in scheduling routine quality checks, shift rotations, or equipment maintenance. Automatic time-zone conversion supports global suppliers and distributed operations, and reminders reduce the risk of forgotten deadlines. Calendar events can also be accompanied by linked documents or Base records, so that employees arrive with the correct information. By rendering time in their factories predictable and visible, Calendar helps manufacturing organizations ship on time, without last-minute surprises.

Lark Docs: Capturing and evolving quality standards

Quality control needs proper documentation as well. Lark Docs gives manufacturing teams a shared place where SOPs, compliance guidelines, and training materials can be authored and updated together in real time.

Version histories provide accountability, capturing how standards of quality adjust as processes reach new levels of refinement. In-document comments let engineers, managers, and inspectors give feedback right in policies — cutting down on ambiguity. Docs are tied to Calendar events for training or stored in Base for compliance. By making quality standards living and shareable, Docs helps teams stay aligned and consistently hit industry standards.

Lark Approval: Streamlining production decisions with automated workflows

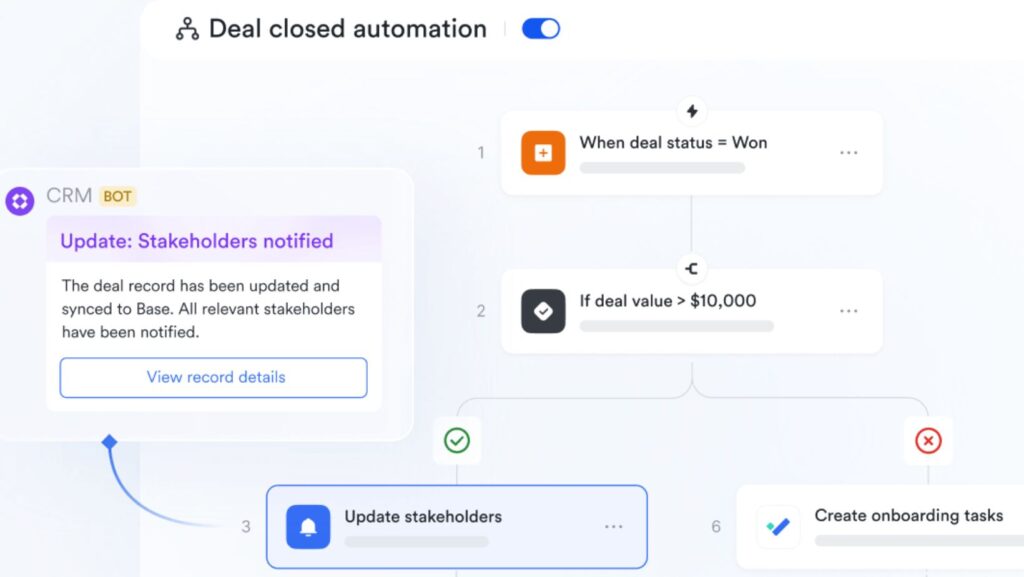

Approvals are a critical part of manufacturing, whether it’s greenlighting production changes, signing off on quality inspections, or approving supplier contracts. Delays in these processes can bring production to a halt. Lark Approval eliminates bottlenecks by structuring how requests and reviews are managed. Employees submit standardized forms, managers approve them with visibility, and every action is logged for accountability.

To reduce delays, Approval supports an automated workflow that routes requests instantly to the right decision-makers. Notifications ensure approvals happen quickly, dashboards provide oversight of pending items, and role-based permissions safeguard sensitive supplier or production information. By embedding automation into approvals, Lark enables manufacturing operations to move forward without compromising quality or compliance.

Lark Sheets: Tracking production metrics in real time

Production efficiency and quality control depend on accurate, real-time data. Traditional spreadsheets often fall short, as they require manual updates and create versioning issues. Lark Sheets transforms this process by offering a collaborative environment where teams can log and track production metrics live.

Throughput, downtime, defect rates, and other KPIs remain updated in real time, ensuring that everyone works from the same data set.

Multiple teams can contribute simultaneously, while dashboards and charts provide instant visibility into performance trends. Sheets also connects data back to Base records or tasks, ensuring insights flow directly into action. By making data transparent and actionable, Sheets strengthens both production timelines and quality outcomes.

Conclusion

Manufacturing is complicated, and nailing it requires balancing speed, precision, and quality. Legacy systems and siloed workflows hold teams back, causing delays and unnecessary risk. Lark solves these problems by bringing together communication, scheduling, documentation, approvals, and data tracking into one platform that keeps production on track and efficient.

With Base centralizing production data, Messenger connecting teams in real-time, Calendar keeping schedules predictable, Docs capturing evolving quality standards, Approval accelerating decision-making through automated workflows, and Sheets ensuring visibility into live metrics, Lark delivers a manufacturing supertoolkit. By bringing these together, it innovates not just effectiveness but also fortifies quality and compliance at scale.

In so doing, Lark serves as a contemporary business process management software competitor — one engineered to assist manufacturers in hitting deadlines, quality control, and scale with assurance.