Choosing the correct sheet metal fabrication provider is a critical decision that can have a big impact on the success of your project. Whether you’re working on a small prototype or a large-scale production run, component quality, lead time, and customer service may all make or break your project. In this post, we’ll go over how to choose a reputable sheet metal fabrication partner and why obtaining a detailed sheet metal estimate is an important step in the selection process.

Assess the Supplier’s Capabilities

The first step in evaluating potential partners is to assess their skills and capabilities. When selecting an appropriate sheet metal fabrication provider, it’s crucial to consider that not many suppliers can handle all types of projects, so it’s essential to choose one that can meet your specific requirements. Consider the following aspects:

- Range of Services: Does the provider provide the services you need, such as cutting, bending, welding, and finishing? Some providers specialize in specific processes, so it’s critical to ensure they can provide all of the services you require under one roof.

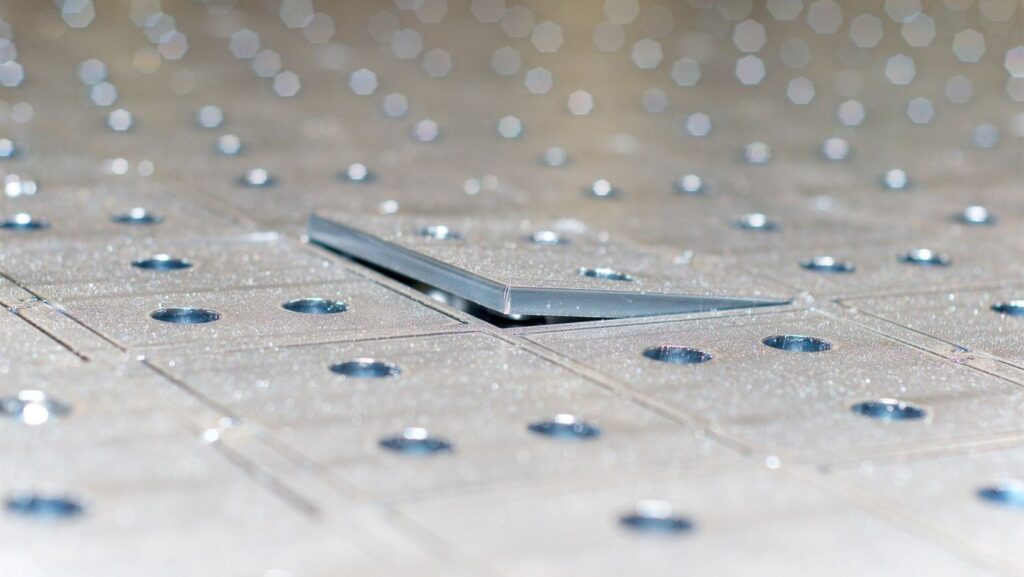

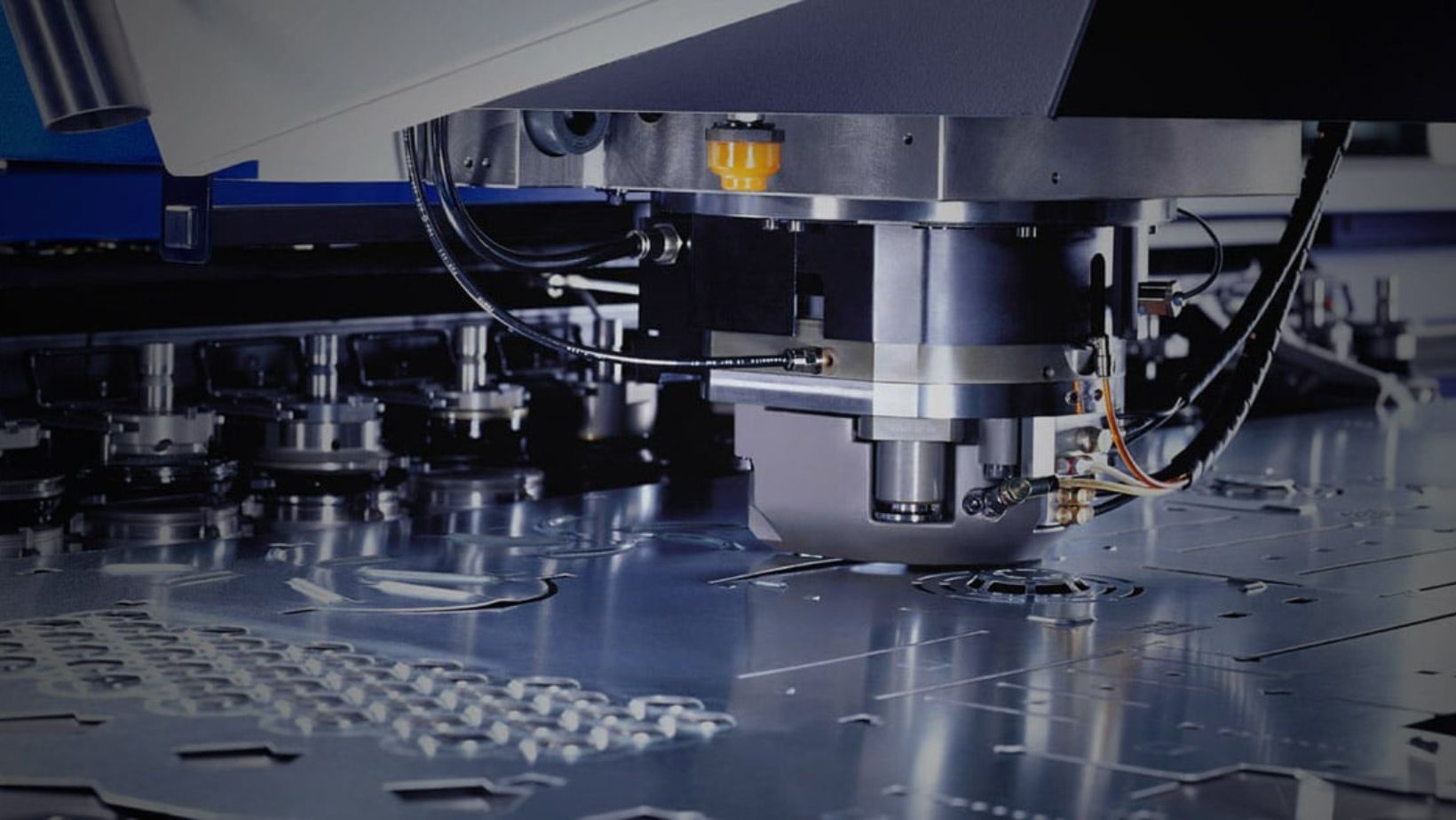

- Equipment and Technology: The supplier’s equipment and technology have a significant impact on the final product’s quality and precision. Ensure that the provider employs current, well-maintained machinery and is knowledgeable with the most recent fabrication procedures.

- Material Expertise: Different projects necessitate different materials, and not all vendors are proficient in working with all types of sheet metal. Check the supplier’s experience with the material you require, such as aluminum, steel, or copper.

Check the Supplier’s Quality Standards

Quality is critical in sheet metal manufacturing since even tiny flaws can cause substantial problems in the finished product. To guarantee you’re collaborating with a supplier who prioritizes quality, examine the following:

- Certifications: Look for suppliers with relevant industry certifications, such as ISO 9001, which demonstrates that they follow high-quality management standards.

- Quality Control Processes: Ask about the supplier’s quality control practices. Do they conduct inspections at various phases of production? How do they handle defective or nonconforming products?

- Past Work Samples: Examining samples of the supplier’s previous work will help you understand their quality standards. Look for uniformity in size, polish, and overall quality.

Evaluate Lead Times and Production Capacity

Meeting project deadlines is critical, so it’s essential to choose a supplier who can deliver within your required timeframe. To evaluate lead times and production capacity, consider the following:

- Current Workload: Ask the provider about their present workload and how it may affect their ability to achieve your deadlines. A supplier who is overworked may be unable to prioritize your project.

- Turnaround Time: Inquire about the normal turnaround time for projects like yours. Keep in mind that faster is not necessarily better; confirm that the provider can retain quality while reaching your deadline.

- Scalability: If your project has the potential to grow, you should find a supplier who can handle higher production quantities without sacrificing quality or lead times.

Consider Customer Service and Communication

Sheet metal fabrication, like any other company partnership, relies heavily on effective communication. A responsive and easy-to-work-with supplier can assist keep your project on track. Here’s what you should look for:

- Responsiveness: How promptly does the supplier answer inquiries? Timely communication is an excellent indication of their overall customer service.

- Transparency: Choose a provider who is open about their methods, timeframes, and prices. They should be willing to answer your queries and provide regular updates throughout the process.

- Problem-Solving: During a project, obstacles will undoubtedly develop. A dependable supplier will be proactive in resolving problems and devising solutions to keep the project on track.

Obtain a Detailed Sheet Metal Quote

One of the most crucial tasks in choosing a sheet metal fabrication company is to receive a detailed sheet metal estimate. This booklet will provide critical information to help you compare vendors and make an informed selection. Here’s why this matters:

- Cost Comparison: A full sheet metal quote enables you to compare the prices of several vendors. Make sure the quote covers all parts of the job, including material prices, labor, tooling, and any additional services such as finishing or assembly.

- Scope of Work: The quote should clearly state the scope of work, including the precise methods and materials to be employed. This ensures that you and the provider have a clear knowledge of the project’s requirements.

- Timeline: The quote should provide an estimate of the project’s timeframe, including important milestones and delivery dates. This will allow you to determine whether the supplier can meet your deadlines.

- Pricing Transparency: A reliable supplier will include a detailed breakdown of expenses in the sheet metal quote. Be skeptical of unusually low quotations, as they may suggest hidden expenses or a compromise on quality.

Review the Supplier’s Track Record

Before making your final decision, check the supplier’s track record. This might provide crucial information about their dependability and reputation. Consider the following.

- Client Testimonials and References: Ask the supplier for client testimonials or referrals. Speaking with prior clients can help you better grasp the supplier’s strengths and flaws.

- Industry Experience: How long has the supplier been doing business? A provider with a long experience in the sector is more likely to have a track record of high-quality work.

- Case Studies: Some providers may offer case studies demonstrating their work on similar projects. These can be useful in determining their capacity to fulfill your specific needs.

Visit the Supplier’s Facility

- Cleanliness and Organization: If feasible, go see the supplier’s facility before making a final decision. This will provide you with firsthand knowledge of their activities, allowing you to better correctly estimate their capabilities. DCleanliness and Organization: A well-organized and clean workplace is frequently indicative of a supplier who takes pleasure in their job and values quality.

- Staff Expertise: Observe the employees at work and inquire about their experience and knowledge. A knowledgeable workforce is critical to your project’s success.

- Equipment Condition: Take note of the state of the equipment and machinery. Production of high-quality components requires well-maintained equipment. During your visit, consider the following.

Conclusion

Choosing the correct sheet metal fabrication provider for your project is an important decision that should be carefully considered. By evaluating the supplier’s capabilities, quality standards, lead times, customer service, and track record, you may identify a partner who will provide high-quality components on time and within budget. Obtaining a precise sheet metal estimate is an important stage in this process since it helps you to compare suppliers and make informed decisions. With the correct provider, you can ensure that your project succeeds and achieves the intended results.