When it comes to upgrading to a 200 amp electrical service, choosing the right wire is crucial for safety and efficiency. This decision impacts everything from the performance of appliances to the longevity of the electrical system. With various wire types and sizes available, understanding the specific requirements can feel overwhelming.

The right wire not only ensures optimal performance but also complies with local electrical codes. Whether it’s for a new installation or a replacement, knowing the appropriate gauge and material is essential. This guide will simplify the process, helping homeowners and like Amped Electric make informed choices for a reliable and safe 200 amp service.

What Wire for 200 Amp Service

Understanding 200 amp service is crucial for homeowners considering electrical upgrades. This service level typically accommodates larger homes or those with high electrical demands. Appliances such as HVAC systems, electric water heaters, and electric ranges often require a substantial amount of power, making the transition to a 200 amp service necessary.

The wire gauge used is vital for ensuring safety and efficiency. For a 200 amp service, the recommended wire size is typically 2/0 AWG (American Wire Gauge) copper wire or 4/0 AWG aluminum wire. These sizes facilitate optimal current flow and minimize the risk of overheating.

Local electrical codes govern the installation process. Compliance with these codes ensures that wiring installations meet safety standards and function properly. Electricians should always verify local regulations before purchasing materials or beginning installation.

Using the correct wire type, such as copper or aluminum, also impacts performance and longevity. Copper offers better conductivity, while aluminum provides a lighter option at a lower cost. Both materials can be suitable when correctly installed and maintained.

Assessing overall load calculations helps determine whether a 200 amp service meets a home’s needs. Homeowners should consider future electrical demands when evaluating power requirements. Upgrading to a 200 amp service can enhance electrical reliability, supporting increased power usage and expanding functionality throughout the residence.

Wire Gauge Requirements

Selecting the appropriate wire gauge is critical for 200 amp service installations, as it ensures safety and efficiency while adhering to established guidelines.

National Electrical Code Guidelines

The National Electrical Code (NEC) sets forth various guidelines for wiring installations, including wire gauge specifications for a 200 amp service. According to NEC Article 310, the selection of wire gauge must account for factors such as ambient temperature, insulation type, and conduit usage. Compliance with NEC standards not only enhances safety but also promotes optimal performance in electrical systems. Homeowners and electricians must reference the most recent NEC version to ensure adherence to these guidelines.

Recommended Wire Sizes

The commonly accepted wire sizes for 200 amp service are:

| Wire Type | AWG Size |

|---|---|

| Copper | 2/0 |

| Aluminum | 4/0 |

2/0 AWG copper wire provides superior conductivity and is more efficient for higher current loads. 4/0 AWG aluminum wire, although less conductive, offers a cost-effective alternative while adequately accommodating 200 amp service. Utilizing these wire sizes minimizes the risk of overheating and enhances the overall reliability of the electrical system. When selecting wire sizes, consider not just the current requirements but also future expansion needs, ensuring the installation can handle potential increases in electrical demand.

Types of Wire Used

Selecting the right type of wire for a 200 amp service installation involves understanding the differences between wire materials and configurations. Two main categories relevant to this topic are copper versus aluminum wire and stranded versus solid wire.

Copper vs. Aluminum

Copper and aluminum serve as primary materials for electrical wiring. Copper wire offers superior conductivity, which enables efficient power transmission with less energy loss. It typically experiences less overheating, making it safer for high-demand applications. Furthermore, copper wires have higher tensile strength, ensuring durability over time.

Aluminum wire, while less conductive than copper, presents a cost-effective alternative. For 200 amp service, using 4/0 AWG aluminum wire remains compliant with electrical standards. Aluminum is lighter and easier to work with, reducing installation challenges. However, it requires proper connections to mitigate oxidation and prevent overheating. Each type’s suitability depends on budget constraints and specific installation requirements.

Stranded vs. Solid Wire

Stranded and solid wire types differ in flexibility and application. Stranded wire consists of multiple small strands twisted together, enhancing flexibility and ease of installation in tight spaces. This flexibility makes stranded wire ideal for situations that involve frequent movements or vibrations.

Solid wire comprises a single solid conductor, providing better conductivity and lower resistance. It works well in fixed installations where flexibility isn’t a priority. For 200 amp service, solid wire may suit permanent connections and applications requiring robust conductivity. Ultimately, the choice between stranded and solid wire depends on the specific installation context and flexibility requirements.

Installation Considerations

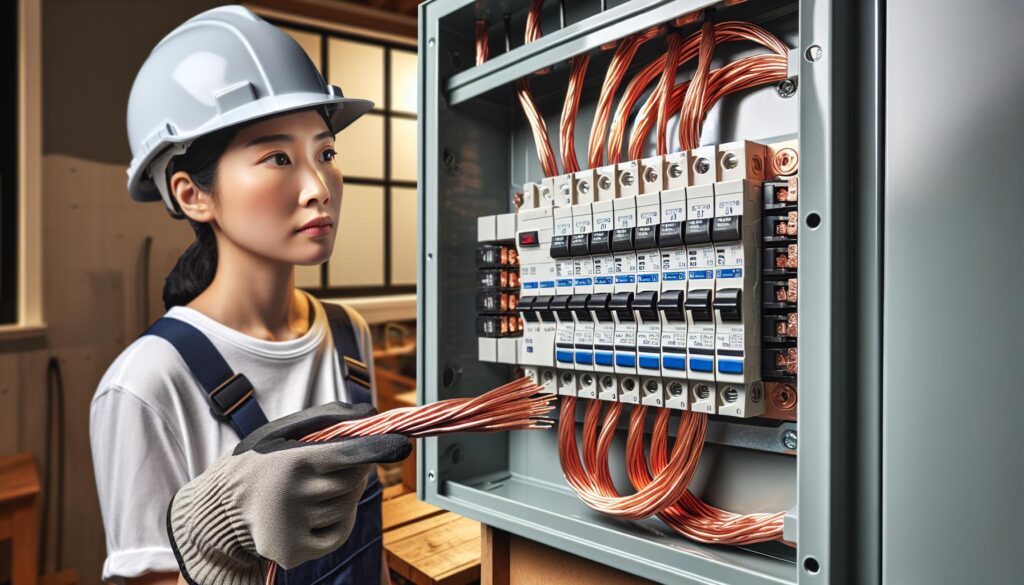

Installation of a 200 amp electrical service requires careful planning and attention to detail. Proper wire selection, along with safety measures, ensures a reliable and compliant electrical system.

Safety Precautions

Safety plays a pivotal role in any electrical installation. Electricians must always turn off the main power before beginning any work. They should wear appropriate personal protective equipment (PPE), including insulated gloves and safety goggles. Adequate grounding and bonding procedures must be in place to prevent electrical shock and ensure system reliability. It’s crucial to follow local electrical codes and National Electrical Code (NEC) guidelines to maintain safety standards during installation.

Tools and Materials Needed

A variety of tools and materials are essential for a successful 200 amp service installation. Key tools include:

- Wire Cutters: For cutting the chosen wire to desired lengths.

- Strippers: For removing insulation from wire ends.

- Crimping Tool: For securing connectors on wire ends.

- Multimeter: For testing voltage, continuity, and current.

- Drill: For installing conduit and securing wiring.

Key materials include:

- 2/0 AWG Copper or 4/0 AWG Aluminum Wire: As specified for optimal current flow.

- Electrical Conduit: To protect wires from damage and environmental factors.

- Wire Connectors: To secure connections and ensure conductivity.

- Circuit Breaker Panel: Suitable for handling a 200 amp service.

Ensuring the right tools and materials are on hand promotes a smooth installation process.

National Electrical Code

Selecting the right wire for a 200 amp service is crucial for ensuring safety and efficiency in any electrical system. Homeowners and electricians must prioritize compliance with local codes and the National Electrical Code to promote optimal performance.

Whether opting for 2/0 AWG copper or 4/0 AWG aluminum wire, understanding the unique properties and applications of each type is essential. Proper installation techniques and attention to detail will further enhance system reliability.

By making informed choices, individuals can accommodate current needs and future demands, ensuring a robust electrical infrastructure for years to come.